In my last article, I talked about memorization as a method for figuring friction loss on the fire scene. In this article we will talk about another fire ground method… the hand method. This method requires a little bit of arithmetic that can become confusing in stressful situations. However, it still is a simple method that can be easily mastered. There are a lot of extremely good pump operators out there that prefer this method. It is similar to the memorization method, in the sense that we will be talking about 1 ¾ diameter hose and all friction loss is figured in 100 feet hose lengths. One major difference between the two is the fact that the memorization method is exact and the hand method is not. It will be plus or minus a couple of psi every time you figure it, but differences will be minuscule and you will probably never find them on the pump panel. Keep in mind this is still just friction loss. You will still have to add your nozzle pressure in order to get your pump discharge pressure. We have provided a training video below but if you continue reading we will go into detail about how to use the Hand Method for calculating friction loss.

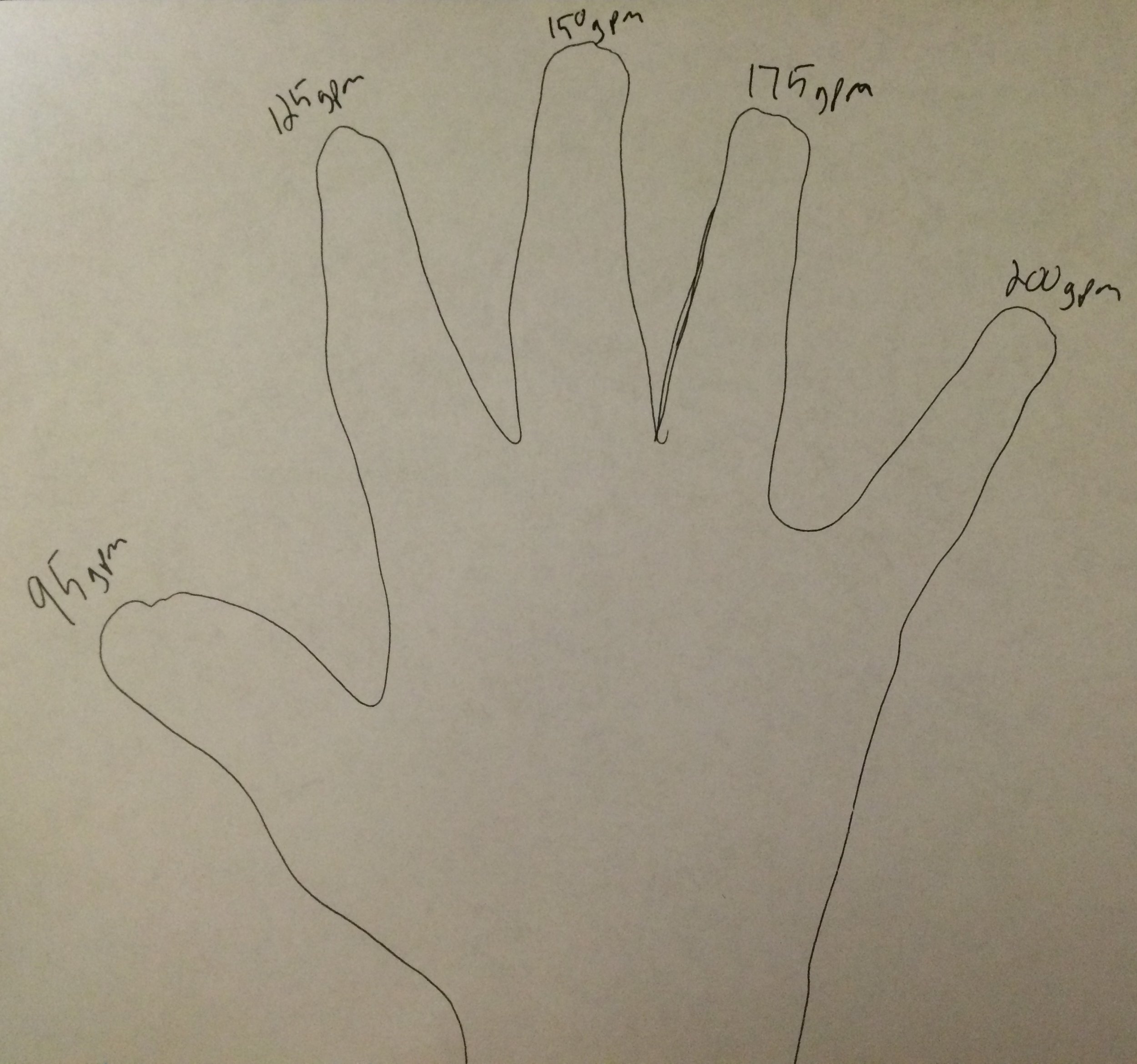

So, lets get started. Here again we will be talking about fog nozzles. Remember, most fog nozzles have four gallons per minute settings… 95gpm, 125gpm, 150gpm, and 200gpm. Now, hold up your left or right hand and spread your fingers. I’m right handed so I will be using my left hand for my descriptions. Imagine your fingers are the gallons per minute settings on the nozzle. Starting with your thumb. The thumb will be 95, index finger 125, middle finger 150, ring finger 175, and pinky finger 200. You can also use these GPM settings for rough estimates on smoothbore nozzle flows if you know them.

STEP 1

The first step is to imagine your GPM settings across your fingertips. This would start with the thumb (95 or 100 GPM) then continue across the remaining fingers. (125, 150, 175, 200 GPM).

STEP 2

STEP 2

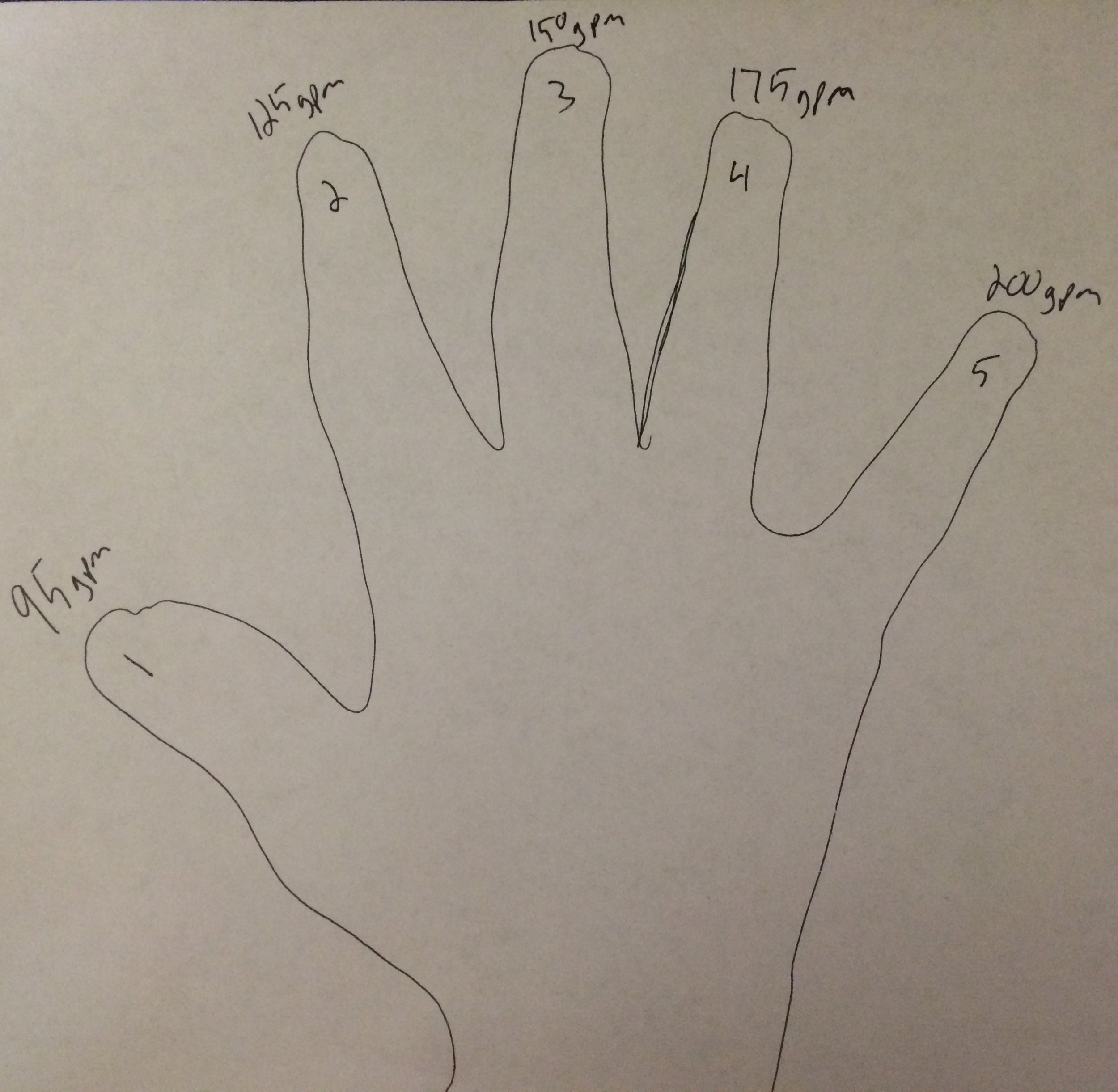

The next step is to number your fingers 1-5. You start by placing the #1 on your thumb followed by 2, 3, 4, and 5 on the remaining fingers.

To finish setting up your hand method you will imagine the number 12 in the palm of your hand.

In order to figure the friction loss, all you have to do is multiply 12 by whatever number or finger you need to use. We will use the same scenarios as we did in the last article.

Lets say you are driving one day and you pull up to a car fire. Your officer and firefighter pull the 100ft jump line and you know you need to be flowing 95 GPM. So, you look at your hand and you notice 95 GPM is at the number 1 position. Multiply 1 x 12.

1 x12 = 12psi

That equals 12. Twelve is your friction loss. If you have a 100psi nozzle just add 100psi. 12psi friction loss plus 100psi nozzle pressure equals 112 pump discharge pressure.

12psi + 100psi = 112psi

You are probably thinking that this isn’t right because it doesn’t equal exactly 114 like the other method. And you are right, it doesn’t. However, I do not know a firefighter in America that can feel a 2psi difference on the end of the nozzle. Its not exact but it will work efficiently.

Next scenario, you are at a structure fire that requires a 200ft line flowing 200gpm. The 200gpm setting is at the number 5 position on your hand, just multiply 5 x 12. It equals 60.

5 x 12 = 60psi

That is 60psi friction loss per 100ft. We have a 200ft line so 60 plus 60 is 120psi total friction loss. Then add your nozzle pressure, 120 plus 100 equals 220psi.

60psi + 60psi + 100psi = 220psi

That is your pump discharge pressure. The exact pump discharge pressure for this scenario would be 224. Here again, I do not know any firefighter that can tell a 4psi difference on the nozzle. If you are using 75psi low-pressure nozzles, it works the same way; just add 75 instead of 100. In terms of friction loss and pump discharge pressure, there are several ways to figure it. On the scene, there are multiple ways to determine friction loss and only one wrong way; that is not getting a proper amount of water to your firefighters. Without it, they can’t put the fire out and could be put in some serious situations because of it. You, as a pump operator, have to figure out how you want to do it. It may be the hand method, memorization, or something else. It doesn’t matter as long as you get the right amount of water to the guys on the nozzle. I hope one of these methods will work for you and next time we will be discussing the Subtract 10 method for calculating friction loss in a 2.5" hose.